In order to convert old paper into de-inked pulp, eleven transformation steps are carried out.

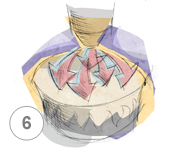

Pulping: Preparation of coarse pulp by mixing old papers with water and breaking them up using the pulper’s powerful agitator. |

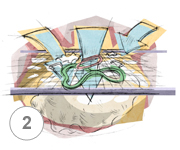

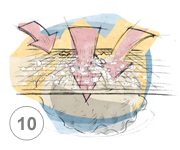

Screening: The pulp is pushed through the screen to remove solid impurities such as staples and glue. |

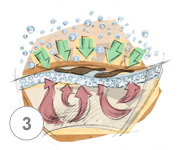

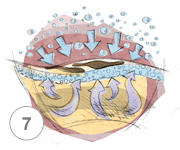

Flotation: Fine soapy bubbles are added to the pulp to bring ink particles to the surface. |

Washing: Visible dirt and glue residue in the water are removed. |

Dispersion: Ink particles are removed by rubbing fibers together. |

Bleaching: The pulp is bleached using hydrogen peroxide, a non-chlorinated component that is environmentally friendly. |

Second Flotation: Fine soapy bubbles are added to the pulp to bring residual ink particles to the surface. |

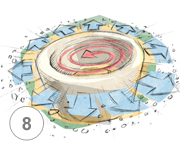

Cleaning: The pulp is put through cleaners, which use centrifugal force to separate the impurities from the pulp. |

Bleaching: In this second phase of chlorine-free bleaching, the degree of whiteness of the pulp increases and any remaining coloring is removed. |

Second Screening: The pulp is pushed through the screen to remove residual sticky particles. |

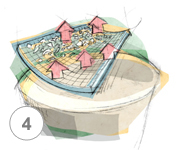

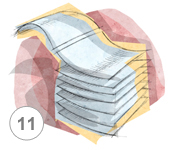

Baling: Thickening the pulp by dewatering, sheeting, cutting and baling. |